Abstract

Environmental Monitoring and Risk Assessment of Cleanrooms within Pharmaceutical Industry

Azam Mehdi1, Muhammad Danish Mehmood2*, Muhammad Usman Ghani2,Muhammad Ismail2, Faisal Ameen3, Saud-ul-Hassan3

Environmental monitoring is a scrutinizing program for microbial and particulate contamination of clean rooms and associated clean

zones for aseptic processing. The current study was therefore, designed to evaluate the quality of clean rooms environment of local

vaccine manufacturing unit in compliance with the international cleanroom standards proposed by the World Health Organization

(WHO) for the production of quality biological products. The classified areas were divided into 60 gridlines where 30 sampling sites

were randomly identified in which 20 critical and 10 non-critical sites were allocated and 700 liters/m3 air was aspirated through air

sampler. Furthermore, particles size of 0.5 um and 5.0 um were also detected for 1 minute from all critical and non-critical sites. It was

revealed that viable count obtained from sampling sites designated as class A of Production Section I and II was less than ≤ 1 CFU/m3.

Whereas, the number of non-viable particles having size of ≤ 0.5 μm in class A at rest were ≤ 3,520 CFU/m3 as compare to 20/m3 of

particle size ≥ 0.5 from each sampling sites in both the sections. Moreover, Finger DAB testing confirmed the hygienic status of

personnel and proper use of antiseptics and sterile garments (�?1 CFU/gloves). Manometer readings in three airlocks in production

section were recorded as 0.05, 0.10 and 0.15 inch of water gauge respectively. Consequently, it is concluded that all sections of

vaccine manufacturing unit are comply with WHO cleanroom standards. In each sampling site of all clean zones shows viable and

non-viable counts within the limits set by local authorities and international cleanroom standards.

Manuscript Submission

Submit your manuscript at Online Submission System

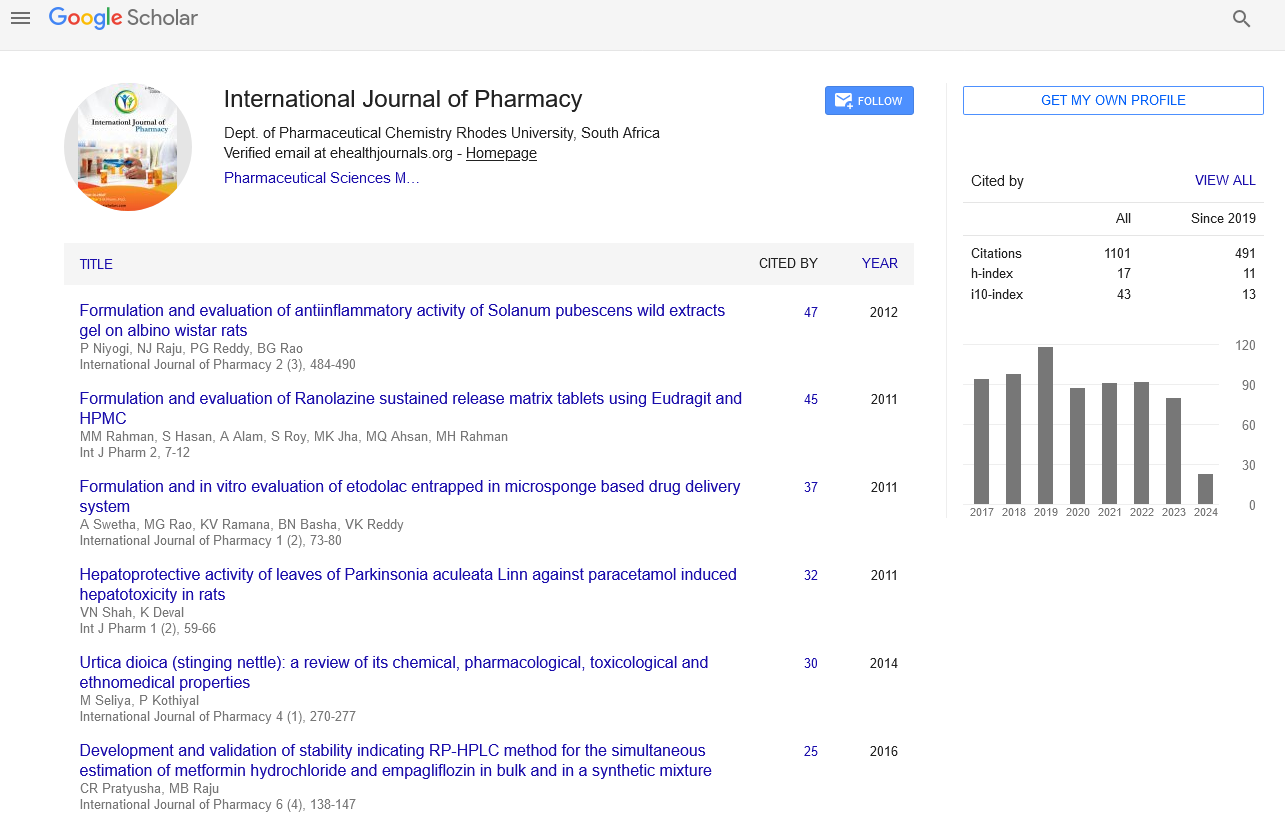

Google scholar citation report

Citations : 1101

International Journal of Pharmacy received 1101 citations as per google scholar report

International Journal of Pharmacy peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- HINARI

- Index Copernicus

- Google Scholar

- The Global Impact Factor (GIF)

- Polish Scholarly Bibliography (PBN)

- Cosmos IF

- Open Academic Journals Index (OAJI)

- Directory of Research Journal Indexing (DRJI)

- EBSCO A-Z

- OCLC- WorldCat

- MIAR

- International committee of medical journals editors (ICMJE)

- Scientific Indexing Services (SIS)

- Scientific Journal Impact Factor (SJIF)

- Euro Pub

- Eurasian Scientific Journal Index

- Root indexing

- International Institute of Organized Research

- InfoBase Index

- International Innovative Journal Impact Factor

- J-Gate