HTML

Commentary - (2023) Volume 13, Issue 6

Ensuring Pharmaceutical Excellence: The Vital Role of Quality Control in Pharmacy

William Hendry**Correspondence: William Hendry, Department of Pharmacy, University of California, California, USA, Email:

Received: 11-Oct-2023, Manuscript No. IJP-23-122703; Editor assigned: 13-Oct-2023, Pre QC No. IJP-23-122703 (PQ); Reviewed: 31-Oct-2023, QC No. IJP-23-122703; Revised: 07-Nov-2023, Manuscript No. IJP-23-122703 (R); Published: 15-Nov-2023, DOI: 10.37532/2249-1848.2023.13(6).75

About the Study

Quality control in pharmacy is a critical aspect of the pharmaceutical industry that ensures the safety, efficacy, and reliability of pharmaceutical products. It encompasses a set of processes and procedures designed to monitor and maintain the high standards required for the production of drugs and other medicinal products. The significance of quality control in pharmacy cannot be overstated, as the consequences of substandard or defective pharmaceuticals can have severe implications for public health.

The primary objective of quality control in pharmacy is to guarantee that pharmaceutical products meet predefined quality standards and comply with regulatory requirements. This involves rigorous testing and monitoring at various stages of the pharmaceutical manufacturing process, from the selection of raw materials to the final product release. The implementation of quality control measures is essential for preventing defects, ensuring consistency, and minimizing risks associated with pharmaceutical products.

One crucial aspect of quality control in pharmacy is the inspection and testing of raw materials used in the manufacturing process. The quality of raw materials directly influences the quality of the final product. Pharmacists must verify that raw materials meet established specifications including purity, identity and strength. This involves continues testing using advanced analytical techniques such as chromatography and spectroscopy. Any deviation from the specified standards may result in the rejection of the raw material or adjustments to the manufacturing process to maintain product quality.

In process quality control is another critical phase in pharmaceutical manufacturing. This involves continuous monitoring and testing of products at various stages of production. Parameters such as temperature, pressure, and reaction times are closely monitored to ensure that the m anufacturing process is operating within established limits. In-process testing testing also includes the assessment of critical quality attributes, such as the uniformity of dosage forms, dissolution rates and content uniformity. By identifying and correcting deviations during the manufacturing process, quality control helps prevent the production of substandard or unsafe pharmaceuticals.

The final step in quality control is the testing of finished pharmaceutical products before they are released to the market. This stage involves a comprehensive evaluation of the product's quality, safety and efficacy. Various tests including physical, chemical and microbiological analyses are conducted to ensure that the product meets all specifications. Pharmacists also verify that the product packaging and labeling comply with regulatory requirements. Only after successful completion of these tests can the pharmaceutical product is released for distribution.

Quality control in pharmacy is not limited to the manufacturing stage; it extends to the storage and distribution of pharmaceuticals as well. Proper storage conditions, including temperature and humidity control, are crucial to maintaining the stability and effectiveness of pharmaceutical products. Additionally, quality control measures are implemented during the distribution process to prevent issues such as product tampering or contamination.

Regulatory authorities play a significant role in ensuring the implementation of quality control standards in the pharmaceutical industry. They establish guidelines and regulations that pharmaceutical manufacturers must adhere to, conducting regular inspections and audits to verify compliance. Adherence to these regulations is not only a legal requirement but also essential for maintaining public trust in the safety and efficacy of pharmaceutical products.

Conclusion

In conclusion, quality control in pharmacy is a multifaceted process that spans the entire lifecycle of pharmaceutical products. It involves rigorous testing and monitoring to ensure that raw materials, manufacturing processes, and finished products meet stringent quality standards. The implementation of quality control measures is essential for for safeguarding public health, preventing the distribution of substandard products, and upholding the integrity of the pharmaceutical industry. As technology continues to advance, the field of quality control in pharmacy will likely evolve, incorporating innovative techniques and methodologies to enhance the precision and efficiency of pharmaceutical testing and monito.r i n g.Manuscript Submission

Submit your manuscript at Online Submission System

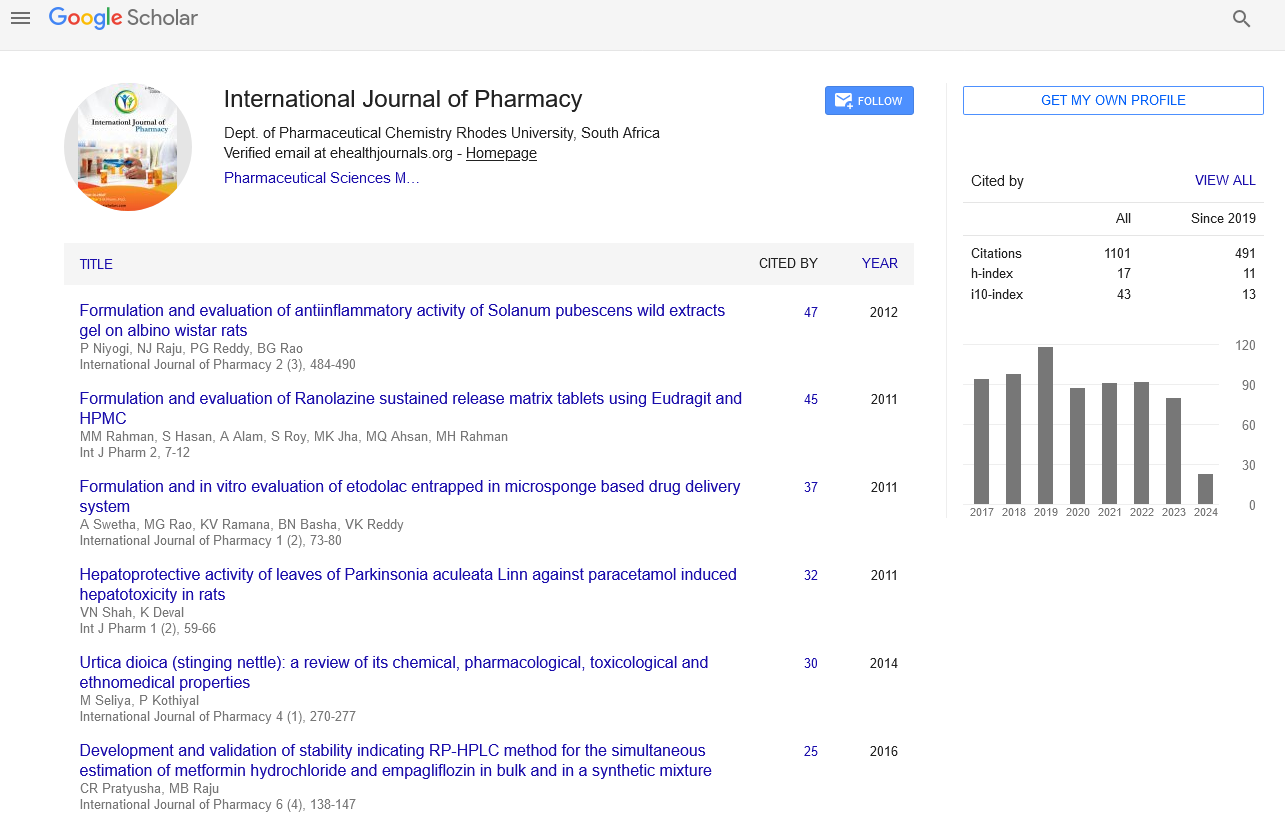

Google scholar citation report

Citations : 1101

International Journal of Pharmacy received 1101 citations as per google scholar report

International Journal of Pharmacy peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- HINARI

- Index Copernicus

- Google Scholar

- The Global Impact Factor (GIF)

- Polish Scholarly Bibliography (PBN)

- Cosmos IF

- Open Academic Journals Index (OAJI)

- Directory of Research Journal Indexing (DRJI)

- EBSCO A-Z

- OCLC- WorldCat

- MIAR

- International committee of medical journals editors (ICMJE)

- Scientific Indexing Services (SIS)

- Scientific Journal Impact Factor (SJIF)

- Euro Pub

- Eurasian Scientific Journal Index

- Root indexing

- International Institute of Organized Research

- InfoBase Index

- International Innovative Journal Impact Factor

- J-Gate