HTML

Perspective - (2023) Volume 13, Issue 6

Good Manufacturing Practices (GMP) in Pharmaceuticals: Ensuring Quality and Safety

Jurun Mclean**Correspondence: Jurun Mclean, Department of Pharmacy, University of California, California, USA, Email:

Received: 05-Oct-2023, Manuscript No. IJP-23-122702; Editor assigned: 09-Oct-2023, Pre QC No. IJP-23-122702 (PQ); Reviewed: 26-Oct-2023, QC No. IJP-23-122702; Revised: 03-Nov-2023, Manuscript No. IJP-23-122702 (R); Published: 10-Nov-2023, DOI: 10.37532/2249-1848.2023.13(6).74

About the Study

The pharmaceutical industry plays a crucial role in public health by producing medications that treat and prevent various diseases. To guarantee the safety, efficacy, and quality of pharmaceutical products, regulatory agencies and industry stakeholders adhere to a set of stringent standards known as Good Manufacturing Practices (GMP). GMP encompasses a comprehensive set of guidelines and procedures designed to ensure that pharmaceutical products are consistently produced and controlled to meet the highest quality standards.

Background of Good Manufacturing Practices (GMP)

The concept of GMP originated in the early 20th century, as the pharmaceutical industry began to grow rapidly. Concerns about the quality and safety of drugs led to the development of regulations and standards to govern the manufacturing processes. GMP was formally introduced as a set of guidelines in the 1960s and has since evolved to keep pace with technological advancements and global regulatory expectations.

For more severe pain, opioid analgesics may be prescribed under careful supervision. However, due to the potential for abuse and addiction, pharmacists play a critical role in ensuring proper dispensing, educating patients on the risks, and monitoring for signs of misuse. Adjuvant medications, such as antidepressants and anticonvulsants, are often employed to manage neuropathic pain. Pharmacies facilitate the distribution of these medications, contributing to comprehensive pain management plans tailored to individual patient needs.

Core Principles of Good Manufacturing Practices (GMP)

GMP is founded on several key principles that underpin the manufacturing and distribution of pharmaceutical products.

Quality management: GMP emphasizes the implementation of a robust quality management system to ensure that every aspect of the manufacturing process is controlled and documented.

Risk management: Identifying and mitigating potential risks to product quality is a fundamental aspect of GMP. This includes assessing and managing risks related to raw materials, processes, equipment, and personnel.

Documentation and record keeping: Accurate and comprehensive documentation is critical in GMP. All aspects of the manufacturing process, from raw material procurement to product distribution, must be well-documented to provide a traceable and transparent record.

Personnel training: GMP emphasizes the importance of adequately trained and qualified personnel. Well-trained employees are essential for maintaining a culture of quality and compliance.

Facility and equipment maintenance: GMP requires that manufacturing facilities and equipment are designed, operated, and maintained to prevent contamination and ensure product quality. Regular maintenance and calibration are essential components of this principle.

Implementation of GMP: The implementation of GMP involves adherence to a set of guidelines that cover various aspects of pharmaceutical manufacturing. These guidelines are typically outlined by regulatory agencies such as the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the World Health Organization (WHO). Manufacturers are required to establish and follow Standard Operating Procedures (SOPs) that detail how each aspect of production and quality control should be conducted.

Manufacturers must also conduct thorough risk assessments to identify potential hazards and implement controls to mitigate these risks. This includes assessing the quality of raw materials, ensuring proper storage conditions, and validating critical manufacturing processes.

Global harmonization of GMP: In an increasingly globalized pharmaceutical industry, harmonization of GMP standards has become a priority. Efforts have been made to align GMP requirements across different regulatory authorities to facilitate international trade and ensure a consistent level of quality worldwide. Organizations such as the International Council for Harmonization (ICH) of Technical requirements for pharmaceuticals for human use have played a key role in promoting global harmonization.

GMP and regulatory inspections: Regulatory authorities routinely inspect pharmaceutical manufacturing facilities to ensure compliance with GMP standards. These inspections are thorough and cover all aspects of the manufacturing process, including facility design, personnel training, quality control, and record-keeping practices. Non-compliance can result in regulatory action, ranging from warning letters to product recalls and facility shutdowns.

Benefits of Good Manufacturing Practices (GMP): The implementation of GMP brings several benefits to the pharmaceutical industry and, ultimately, to patients.

Ensuring product quality: GMP helps maintain consistently high product quality by establishing and enforcing rigorous standards throughout the manufacturing process.

International collaboration: Global harmonization of GMP standards promotes international collaboration, facilitates trade, and ensures that pharmaceutical products meet uniform quality standards across borders.

Regulatory compliance: GMP compliance is a regulatory requirement in most countries. Adhering to GMP helps pharmaceutical companies meet regulatory expectations and gain approval for their products.

Conclusion

Good Manufacturing Practices are the cornerstone of the pharmaceutical industry, providing a framework for the production of safe and effective medications. As the industry continues to evolve, adherence to GMP remains essential to ensure the quality, safety, and efficacy of pharmaceutical products worldwide. By embracing the principles of GMP, manufacturers contribute to the trust and confidence that patients and healthcare professionals place in the pharmaceutical industry.Manuscript Submission

Submit your manuscript at Online Submission System

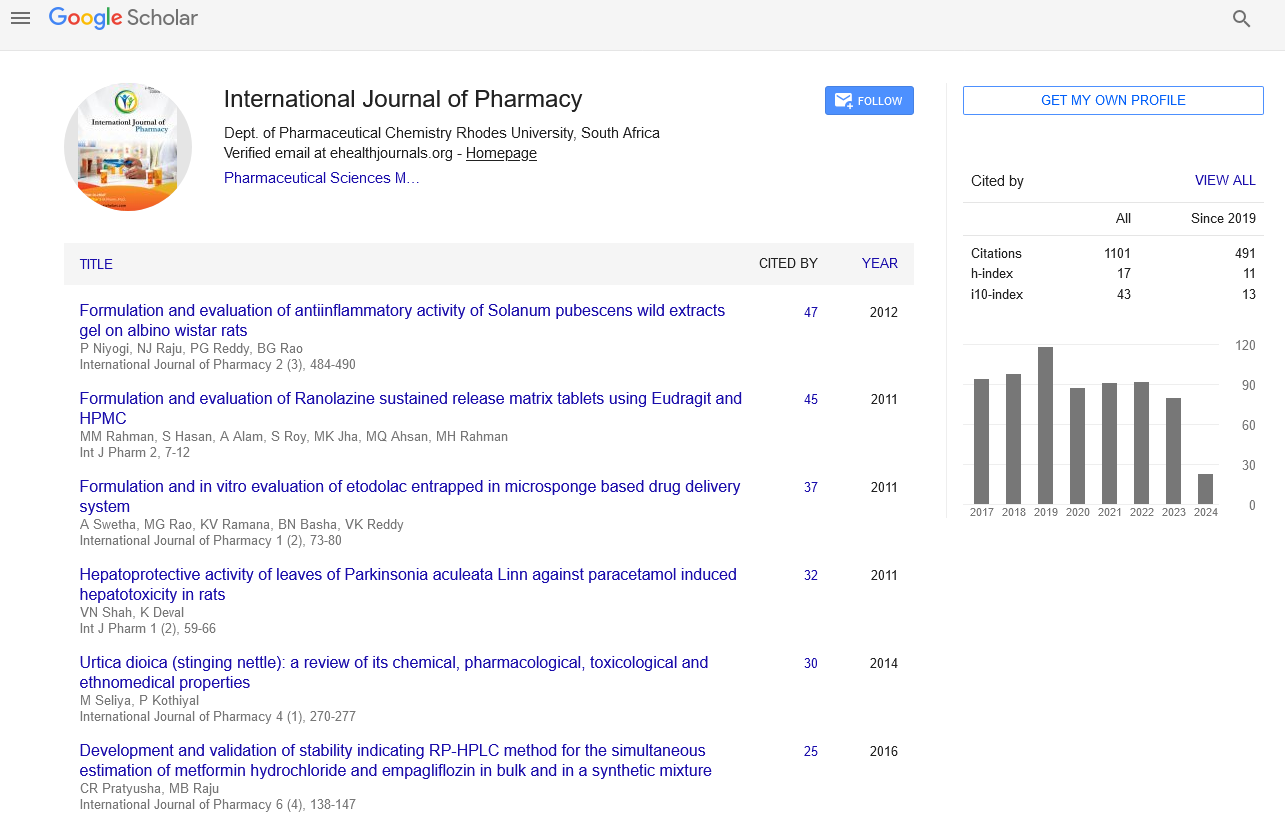

Google scholar citation report

Citations : 1101

International Journal of Pharmacy received 1101 citations as per google scholar report

International Journal of Pharmacy peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- HINARI

- Index Copernicus

- Google Scholar

- The Global Impact Factor (GIF)

- Polish Scholarly Bibliography (PBN)

- Cosmos IF

- Open Academic Journals Index (OAJI)

- Directory of Research Journal Indexing (DRJI)

- EBSCO A-Z

- OCLC- WorldCat

- MIAR

- International committee of medical journals editors (ICMJE)

- Scientific Indexing Services (SIS)

- Scientific Journal Impact Factor (SJIF)

- Euro Pub

- Eurasian Scientific Journal Index

- Root indexing

- International Institute of Organized Research

- InfoBase Index

- International Innovative Journal Impact Factor

- J-Gate