HTML

Research - (2021) Volume 11, Issue 11

Nanocrystal Technology, Characterization and Pharmaceutical Applications

Aijaz A Sheikh, Amol J Giri*, Arif Sheikh, RH Kale and KR Biyani*Correspondence: Amol J Giri, Department of Pharmacy, Samarth College of Pharmacy, Pune, Maharashtra, India, Email:

Received: 19-Nov-2021 Published: 10-Dec-2021

Abstract

Today one of the greatest challenges in drug delivery is the poor solubility of new chemical entities. Approximately seventy to ninety percent of new chemical entities are having solubility issues. One relatively simple approach to improve drug dissolution and solubility properties is formulation as nanocrystals. Drug nanocrystals are solid nanosized drug particles surrounded by a stabilizer layer; sometimes they are also referred to as solid micelles. Typically, their size ranges from approximately 200 to 800 nm, depending on the application. Drug nanocrystals have comparatively simple structures which make them attractive for the formulation for poorly soluble drugs, and their capability to improve the dissolution in vitro is easily demonstrated. The present review basically deals with the nanocrystals, its physical properties, current technologies for producing drug nanocrystals i.e. top-down, bottom-up, and combinative. The review also focuses on sterilization, stability and characterization of nanocrystals with its pharmaceutical applications.

Keywords

Drug nanocrystals, Drug delivery, Stabilizers, Top-down techniques, Sterilization, Raman spectroscopy, Nanocrystal applications.

Introduction

Drug nanocrystals are without any doubt one of the most discussed drug delivery technology of the past twenty years. Drug nanocrystals are the nanoparticles which offer an advantage of 100% drug loading since they are encapsulating-carrier free nanoparticles. Nanocrystals formulation contains drug and one/more stabilizers dispersed in aqueous or non-aqueous media. Stabilizers could be one or more generally regarded as safe excipients (surfactants or buffers, salts or sugars) [1,2]. The liquid dispersion nanocrystals could be further post processed into solid or sterile injectable dosage forms. The therapeutic applications of nanocrystals products have been identified in oral, parenteral, ocular, dermal, pulmonary, and targeted drug delivery.

Nanocrystals, further offer flexibility of upscaling and downscaling which could be of great value whenever alterations with respect to unit operation functions or formulation are desired during scaling up process [3]. The formulation simplicity and production scaling flexibility along with their intrinsic small particle size and large surface area make nanocrystals stand a way unique not just among the pharmaceuticals but also among other nanoparticles.In this paper, we reviewed physical properties of nanocrystals and drug nanocrystal technologies. Additionally, characterization of nanocrystals and pharmaceutical applications of drug nanocrystals were also discussed [4].

Methodology

Physical properties of nanocrystals

The therapeutic advantages of nanocrystals are predominantly due to reduction in particle size (less than 1 mm). Suspensions of nanocrystals with 100% drug loading are much simpler and easier to prepare and scale-up than carrier based nanoparticles, nanocapsules or nanospheres, with only the need for stabilization. Nanocrystals will also have similar gains in bioavailability and the relative monodispersity minimizes the likelihood of Ostwald ripening. Improved solubility and dissolution is due to higher saturation solubility and dissolution velocity as a result of the increase in surface area, and the reduction in particle radius (Kelvin equation) [5,6]. Enhancement in bioavailability can also be attributed to partial or full conversion to the amorphous form upon processing, with the metastable form or nanocrystalline phase having higher surface energy. Also it has been shown that increased adhesion may lead to improved oral absorption. Surface functionalization can alter and further enhance properties of nanocrystals depending on the needs for release profile and targeted drug delivery.

Drug nanocrystal technologies

One of the conventional size reduction techniques in pharmaceutical industry is milling, a process of micronization that reduces drug particle sizes to 2-3 μm [7-10]. Unfortunately, microparticles from milling have the problem of agglomeration which may decrease the surface available for dissolution. During the past two decades, technologies to reduce particle sizes to nano-meter range (<1 μm) are now achievable and are more attractive approaches for poorly water-soluble drugs. The three categories of technologies currently producing drug nanocrystals are top-down, bottom-up, and combinative.

Top-down techniques

The top-down process is an established disintegration method which is a high energy process. The drug particles are reduced to smaller sized particles by the use of technologies such as milling technologies and highpressure homogenization. The top-down process is universally and industrially more feasible than other processes. There are a number of patents and marketed products available using the top-down approach. Wet Ball Milling (WBM, also called as Pearl milling or Bead milling) is an important industrial technology– for particle size reduction that can utilize almost any Active Pharmaceutical Ingredients (API) to prepare nanosuspensions. WBM is (Figure 1) superior over standard High Pressure Homogenization (HPH) because it is possible to use WBM to produce nanosuspensions with minimal API quantities, making WBM the preferred method for formulation studies. During the process, the milling chamber is charged with milling media, water, drug, and stabilizer. The high energy shear forces and/or the forces generated during impaction of the media with the drug provide the energy input required to fracture the drug into nanocrystals. Drugs that are poorly soluble in both aqueous and organic media can be easily formulated into nanosuspensions by WBM. The benefits of WBM are in its ease to scale-up, limited batch-to-batch variation, narrow nanocrystal size distribution, and flexibility in handling the drug quantity. The disadvantages of WBM include residues from milling media, slow process, and instability.

There are two kinds of WBM: Low Energy Ball Milling (LE-WBM) and High Energy Ball Milling (HE-WBM). LE-WBM is the simplest method, using a jar filled with milling media like very simple glass beads. The API, preferably in micronized form, is suspended in dispersion medium containing stabilizer(s) and the milling beads are then moved by either an electric stirrer or the entire jar could be moved by a roller plate or mixer. Milling times can take several days due to low input energy.

With HE-WBM, production times are signiicantly reduced via its much higher power density. There are two modes available in HEWBM : batch and continuous (re-circulation). High energy mills require special milling media which must take into account the inner surface material of the mill, agitator types, among other factors.

Smaller or larger coated milling pearls of ceramics, stainless steel, glass, or highly cross-linked polystyrene resin-coated beads can be used. NanoCrystal™ (Perrigo) utilizes this technique and HE-WBM is now a standard method in producing nanosuspensions. High-Pressure Homogenization (HPH), the second most important technique in producing drug nanocrystals, is a high-energy disintegration process in which high pressure is used to reduce the particle size of API in liquid media with surfactants. The main mechanisms of HPH size reduction are via cavitation forces, shear forces, and collision.

There are two kinds of homogenization techniques used to produce nanosuspensions: Piston-Gap homogenization and Jet-Stream Homogenization (microfluidization). In the former, size reduction is achieved by cavitation, shear forces, and particle collision. The suspension is forced through a small gap, which reduces the particle diameter from 3 cm to approximately 25 μm. In Jet-Stream Homogenization, size reduction is achieved by the piston-gap homogenization method.

Bottom-up techniques

The bottom-up process grows nanocrystals from solution, which includes two crucial steps: nucleation and consequent crystal growth. In comparison, nucleation is especially important to achieve small and uniform nanocrystals. Higher nucleation rate increases the number of nuclei formed from the supersaturated solution, leading to decreased supersaturation. Less growth of each nucleus in the end can be anticipated as a consequence. Also, if a large number of nuclei are produced concurrently in the nucleation stage, a narrow particle size distribution is obtained. Therefore, it is essential to promote rapid and homogeneous nucleation in the bottom-up process. Nucleation can be triggered by either mixing with antisolvent or removal of solvent. The mixing of drug solution and antisolvent is generally achieved with conventional mixing equipment, i.e. magnetic stirring and agitator blade. In order to promote the nucleation, sonication can be introduced to provide cavitation effects (Figure 2). This method is called sonoprecipitation. Some highly efficient mixing equipment have also been used to prepare nanocrystals, including confined impinging jet reactor, multiple inlet vortex mixer and static mixer. With these instruments, intense micro-mixing between the two fluids is fulfilled in the order of milliseconds. A homogeneous solution with high supersaturation may be achieved even before the onset of nucleation, favoring small nanocrystals with narrow size distribution. Spray-drying and freeze-drying are common ways to remove solvent. Recently, spray-freezing into liquid and controlled crystallization during freezedrying techniques also has been developed to prepare nanocrystals by removal of solvent. Supercritical Fluid (SCF) can be used to prepare nanocrystals by taking advantage of the unique physical properties of SCF, with combined diffusivity like gas and solubilization like liquid. In addition, quick and easy removal of SCF without excessive drying can greatly facilitate the precipitation of nanoparticles. Supercritical carbon dioxide (SCO2) is the most favored SCF due to the mild critical point (31 C and 73.8 bar) and low environmental impact.

Figure 2. Schematic illustration of bottom-up techniques in which crystallization is triggered by solvent/anti-solvent mixing. 2A: Sonication can be combined with a common mixing instrument such as magnetic stirring to promote nucleation; 2B: With highly efficient mixing equipment, including confined impinging jet reactor; 2C: multiple inlet vortex mixer and static mixer; 2D: intense micro-mixing may be achieved even before the onset of nucleation, favoring small and homogeneous nanocrystals.

Precipitation coupled with high energy processes (combinative technologies)

The standard top-down and bottom-up technologies used to produce drug nanocrystals have the limitations that a micronized drug is required as the starting material and the top-down equipment has long runtimes. In combinative technologies, energy is supplied by High Pressure Homogenization (HPH), ultrasonic wave, and high energy mixing coupled with a precipitation process. They have been developed to overcome the drawbacks of the standard process [11,12]. The advantage of the combinative technology is that it can be tailormade to drug properties. Nanoedge® Technology (Baxter) is the first combinative technology used to produce drug nanosuspensions. The process includes microprecipitation (a solvent-antisolvent technique) which is followed by a high-energy annealing process such as HPH, sonication, or microfluidization.

H69 Technology (PharmaSol) is similar to the Nanoedge® Technology, and microprecipitation is followed by HPH. In H69 technology, cavitation happens either at the same time as or two seconds later than particle formation. The drug is first dissolved in a solvent and then, in a controlled manner, an aqueous non-solvent is mixed with the solvent. Drug precipitation will occur when the two liquids contact each other. Particle formation happens in the high-energy zone of a homogenizer and the drug particles are treated with cavitation, particle collision, and shear forces [13-17].

H42 Technology (PharmaSol) combines Spray Drying (SD), a precipitation and a pre-treatment step, followed by a particle size reduction step by HPH. The bottom-up step does not include an organic solvent and this differentiates the H42 from the Nanoedge® and H-69 technologies. In the spray drying step, the drug is dissolved in an organic solvent with or without surfactants. After the spray drying, more breakable drug powders are formed and ready for the next comminution step. The drug powders are dispersed in aqueous media containing surfactants and the suspensions will then be processed to nanosuspensions using the HPH technique. This belongs to the smart Crystal® technology (Abbott/Soliqs, Germany) family and was developed by Moschwitzer and colleagues [18-21].

H96 Technology (PharmaSol) includes a lyophilization (freeze-drying, FD) which is followed by HPH. It was developed by Moschwitzer and Lemke and also belongs to the smartCrystal® technology (Abbott/ Soliqs, Germany) family. In the first freeze-drying step, the drug organic solution is frozen with liquid nitrogen and further freezedried. This pretreatment could effectively increase the particle size reduction of the HPH. The low temperatures and high yields of the FD make it suitable in processing thermolabile or expensive drugs. The FD step eliminates the organic solvent content and makes the nanosuspensions ready to be processed or used. The drawback to this method is the extension of the FD step.

Combinative Technology does not employ organic solvents, making it different from the other combinative processes. The combinative Technology includes a low-energy pearl milling step followed by HPH. The milling of the macrosuspension in the pretreatment could produce drug particle sizes ranging between 600 and 1500 nm. After the HPH step, the particle size will be further reduced and a nanosuspension with more homogeneity will be formed. The advantages are in the reduction of the homogenization pressure, process length, and the improved physical stability of the nanosuspensions. The drawback is that the particle sizes are relatively bigger than the other combinative processes.

Sterilization of obtained nanocrystals is an important step during the production, especially for the products intended for parenteral use. Generally, for sterilization, two major approaches, that is, thermal sterilization and aseptic production, are employed. Alternatively, sterilization techniques like gamma irradiation could be performed for the effective sterilization of prepared nanocrystals. Thermal sterilization by autoclaving is preferred when the drug nder study is highly thermal resistant. Also, strict care is taken to accommodate any stability issues arising from the stabilizer used in the preparation. Generally, nanocrystal preparations stabilized by surfactants such as lecithins are stable at autoclaving conditions. On the other hand, stearic stabilizing stabilizers such as poloxomer 188 have shown problems such as flocculation during the autoclaving process. Another widely exercised sterilization approach for nanocrystals is aseptic production, which operates during the production stages. These processes can be easily monitored and precisely validated. These consist of an aseptic setup of equipment and conditions that can be employed for largescale parenteral nanocrystalsuspensions. Homogenization process at high pressure also acts as a sterilization process for disintegrating microorganisms along with its size reduction effect on nanocrystals (Table 1).

| Drug | Indication | Process | Special notes |

|---|---|---|---|

| Aprepitant | Antiemetic | Milling | Faster absorption and higher bioavailability |

| Fenofibrate | Hyperlipidemia | Milling | Higher bioavailability, easier administration |

| Sirolimus | Immunosupressant | Milling | Higher bioavailability |

| Megestrol acetate | Anti-anorexic | Milling | Reduced dosing |

| Morphine sulfate | Psychostimulant | Milling | Higher drug loading and bioavailability, extended release |

| Dexamethyl-phenidateHCl | Psychostimulant | Milling | Higher drug loading and bioavailability |

| TizanidineHCl | Muscle relaxant | Milling | Higher drug loading and bioavailability |

| Palperidonepalmitate | Schizophrenia | Milling | Allows slow release of injectable low solubility drug |

Stability of nanocrystals

Conversion of drug particles to nanosize resulted in creation of new interfaces which results in increase in a positive Gibbs free energy change. This change in energy makes the system thermodynamically unstable. To acquire stability, nanocrystals tend to agglomerate and resulted in crystal growth. This subtle change in particle size leads to dramatic alteration in the properties of nanocrystals [22].

Stabilizers are used to decrease the free energy of the system and to provide stability to the system over a prolonged period of time. These stabilizers adsorb on to the surface of nanocrystals and creates a rough or charge surface, depending on the property of the stabilizer, which prevents coalescence of the particles and hence prevent increase in particle size or crystal growth. Stabilizers can be divided in three categories: polymeric (Polyvinyl alcohol (PVA), Polyvinylpyrrolidone (PVP), Hydroxypropyl Cellulose (HPC), Hydroxypropylmethyl Cellulose (HPMC)), ionic surfactant (Sodium Lauryl Sulfate (SLS), sodium dodecyl sulfate (SDS), polyethyleneimine (PEI)), and nonionic surfactants (poly(ethylene oxide)-poly(propylene oxide) (PEO-PPOPEO) or Pluronics®, Tween, Soluplus®, D-α-Tocopherol Polyethylene Glycol Succinate (TPGS)). These stabilizers provide stability to the system either by steric repulsion (polymeric and nonionic stabilizers) or electrostatic repulsion (ionic stabilizers).

Properties of drug molecules (logP, enthalpy, presence of hydrophilic, hydrophobic or charged moieties, etc.) and stabilizer (molecular weight, chain length, presence of charge, etc.) governs the interaction between them and hence stability of the system [23-25]. For example, HPC and PVP are suggested stabilizers for the drug molecules having hydrophobic surfaces without polar functional groups. Faster and strong interaction between drug and stabilizer is required for a stable system. However, selection of suitable stabilizer or combination of stabilizers, to make a stable system, requires formulation of nanocrystal batches individually or in combination of stabilizer and compares their properties (particle size and size distribution, zeta potential, crystallinity, and stability) [26].

Characterization of nanocrystals

Solid state properties: Different nanocrystals manufacturing conditions and procedures can have an impact on the ensuing solid state form. Furthermore, the environmental conditions affect the thermodynamically stable polymorphic form. For e.g., hydrate forms are generally more stable (and therefore less soluble) in aqueous media. Therefore if the drug is susceptible to hydrate formation, then the potential or factors triggering the said conversion should be extensively investigated during stability studies in different conditions. X-Ray Powder Diffraction (XRD), thermal analytical techniques (differential scanning calorimetry, thermogravimetry, etc.) and vibrational spectroscopy (infrared and Raman) are the most commonly used methods to determine and monitor the solid state form of nanocrystals.

Particle size and size distribution: The most frequently used techniques for particle size measurements of nanosized systems are dynamic light scattering techniques, static light scattering techniques and microscopy. The mean particle size of nanosuspensions is typically analyzed by dynamic light scattering also known as Photon Correlation Spectroscopy (PCS). Techniques for the detection of larger particles are optical microscopy and low angle static light scattering (laser light diffraction), especially for the nanosuspensions that are meant for parenteral and pulmonary delivery. A Coulter counter analysis is essential for nanosuspensions to be administrated intravenously. Apart from these, the other techniques used for the particle size analysis include confocal laser scanning microscopy, scanning probe microscopy, and scanning tunnelling microscopy.

Particle shape and morphology: Ideally, the shape or morphology of the nanocrystals can be determined using a Transmission Electron Microscope (TEM) and/or a Scanning Electron Microscope (SEM). Atomic Force Microscopy (AFM), a kind of scanning probe microscope is designed to measure local properties, such as height, friction, magnetism with a probe.

Particle surface charge: The particle surface charge is ideally quantified in terms of the zeta potential, which is measured via the electrophoretic mobility of the particles in an electric field. The particle charge can be measured in surface charge per unit, determined by colloid titration.

Thermal analysis: Differential Scanning Calorimetry (DSC) is one recurrently used method for studying the thermal behavior of drug and drug nanocrystals. Among other thermal techniques, hot stage microscopy (also known as Thermal Microscopy or Thermomicroscopy) is a combination of microscopy and thermal analysis to enable the study and physical characterization of materials as a function of temperature and time. Thermal analysis may also be performed by thermogravimetric measurements or Differential Thermal Analysis (DTA).

Raman spectroscopy: It is used as a tool to characterize the phase transitions and phase of different types of nanoparticles and other nanomaterials (e.g., nanocrystal) to identify the regions of nanostructured materials as crystalline or amorphous. It is also used to determine the defects in the nanomaterials, size, shape of nanomaterials, and nanostructured material distribution as homogenous or heterogeneous. It has been widely employed in pharmaceutical science such as fundamental structural examination, drug excipient compatibility studies, formulation characterization, quantitative analysis, and investigation of surface modification in nanoformulation.

Permeation study: The permeation studies are usually done by using the Franz diffusion cell apparatus. The human cadaver skin, pig ear skin, rat skin, and pig skin can be used for the same.

Discussion

Nanocrystal applications

Oral drug delivery: The oral route is the most preferable and safest delivery route compared with other routes of administration. It facilitates bio adhesion in the wall of the intestine; therefore, enhanced oral bioavailability of poorly soluble drugs was found. The bioavailability can be determined by calculating the pharmacokinetic parameters like maximum plasma concentration (Cmax), time to reach maximum concentration in plasma (Tmax), and Area Under the blood Concentration-time curve (AUC). Due to the small particle size of nanocrystals, it enhances uniform distribution in the GIT and reduces local prolonged concentrations. Nanocrystals are also well tolerable in the mucosal as it causes minimal gastric irritation. Additionally, orally used nanosuspensions of fenofibrate show enhancement in bioavailability as compared with conventional micronized drug suspensions.

Parenteral drug delivery: Nanocrystals can increase the effectiveness of drugs via various parenteral routes such as intravenous, subcutaneous, intramuscular, intraarticular, and intraperitoneal. In conventional drug delivery system, an intravenous formulation of poorly soluble drugs needs various excipients like surfactants and cosolvents. But these lead to an increase in dose volume as well as cause various adverse reactions. Due to small particle size, nanocrystals can be given by intravenous injection with the reduced dose, fast onset of action, and achieved maximum bioavailability. For the parenteral route of administration, nanocrystals size should be ≤ 100 nm. There are various suitable nanocrystals successfully drug delivered through the intraperitoneal route. Paclitaxel nanosuspension showed promising result in comparison with pure taxol to the reduction of median tumor burden.

Pulmonary drug delivery: The drug deposition on the lungs can be managed through the size distribution of nanocrystals. The aqueous nanosuspension was prepared by the ultrasonic method for the drug delivery to the lungs. The poorly soluble drugs like beclomethasonedipropionate or budesonide to the pulmonary tract are very crucial for local treatment of lung diseases. Nanocrystals have a tendency to attach to the mucosal surface and give prolonged residential time and hence increase the drug absorption. Nanocrystals exhibit undesired deposition of the particle in the pharynx and mouth which exert local and systemic adverse effects. In comparison with microparticles, Nanocrystals are more equally distributed on the surface of the bronchi. There are various examples available for successful pulmonary drug delivery of nanocrystals.

Ophthalmic drug delivery: Ocular delivery is a challenging system due to eye physiological barriers and critical pharmacokinetic surrounding environments. The topical delivery is the most preferred and noninvasive drug administration route used for the treatment of anterior segment eye diseases. Nanocrystal shows advantages like a long time of residence which is required for the effective treatment of most of the ocular diseases. It also provides low tonicity and their performance depends upon drug intrinsic solubility in the lachrymal fluids. Hence, the intrinsic rate of dissolution of the drug in lachrymal fluids determines its bioavailability and ocular release. The glucocorticoid nanosuspension of drugs like dexamethasone, prednisolone, and hydrocortisone showed increased drug action duration and enhanced drug absorption.

Targeted drug delivery: The targeted drug delivery provides a predominant accumulation of drug within a specifically targeted zone for the treatment. Nanocrystals used for targeted drug delivery show specific interaction with a receptor in targeted tissues. Effectiveness of targeted drug delivery needs four basic requirements: first retain, second evade, third target, and fourth release. Due to being sequestered and transported by MPS cells, i.v. injected nanocrystals distribute more in MPS cell-abundant organs, such as the liver, spleen, and lung than the solution counterpart. The targeting ligands and other functional groups can also be added on the surfaces of nanocrystals. By using this way, nanocrystals can be incorporated into various matrix structures and targeted in a specific tissue/organ for their action.

Conclusion and Future Perspective

Nanocrystal technology seems to be a promising tool for the formulation of poorly soluble drugs. The nanocrystals despite being poorly soluble just dissolve and disappear in the presence of large amount of water. They have been successfully employed to improve the bioavailability, better drug targeting with minimum side effects, reduced drug dosage and hence better patient compliance. They can be incorporated in solid dosage forms like tablets and capsules which are more patient friendly. In the future the research will be headed more on functional properties of the stabilizers utilized in drug nanocrystals, role of supersaturation and QbD approach in formulation design, and drug targeting applications for example in cancer therapeutics or theranostics through the attachment of protecting layers and targeting ligands on the surfaces of the nanosystem. Their nanotoxicity needs to be assessed and more authenticated therapeutic data is awaited. However, nanocrystals hold promise to appear in many future products, not only pharmaceutical but also cosmetic.

Acknowledgement

The authorswould like to thank for their continued support and guidance.

Funding

Nil

Author’s Contributions

All the author have contributed equally.

Conflict Of Interest

There are no conflicts of interest

References

- Manzanares D, Cen V. Pharmaceutics. 2020; 12 (371): 1-22.

- Merisko EL, Liversidge GG, Cooper ER. Eur. J. Pharm. Sci. 2003; 18: 113-20.

- Merisko-Liversidge E, Liversidge GG. Adv. Drug. Deliv. Rev. 2011; 63: 427-40.

- Mohammad IS, Hu H, Yin L, et al. Int. J .Pharm. 2019; 562: 187-202.

- Moribe K, Wanawongthai C, Shudo J, et al. ChemPharm. Bull. 2008;56: 878-80.

- Moschwitzer J, Achleitner G, Pomper H, et al. Eur. J. Pharm. Biopharm. 2004;58 (3): 615-9.

- Mosharraf M, Nystrom C. Int. J. Pharm. 1995;122:35-47.

- Muheem A, Shakeel F, Warsi MH, et al. J. Pharm. Sci. 2017; 106 (10): 3050-65.

- Muller R, Jacobs C. Int. J. Pharm. 2002a; 237:151-61.

- Muller RH, Jacobs C. Pharm. Res. 2002b; 19:189-94.

- Raghava Srivalli KM, Mishra B. Saudi. Pharm. J. 2014; 24 (4): 386-404.

- Raja SN, Bekenstein Y, Koc MA, et al. ACS Appl. Mate.r nterfaces. 2016; 8: 35523-33.

- Reid MS, Villalobos M, Cranston ED. Nanoscale. 2016; 8: 12247-57.

- Salmaso S, Caliceti P. J. Drug. Deliv. 2013; 1: 1-19.

- Sawant KK, Patel MH, Patel K. Drug. Dev. Ind .Pharm. 2016; 42(5): 758-68.

- Schnitte M, Staiger A, Casper LA, et al. Nat. Commun. 2019; 10 (2592):1-6.

- Shafaie S, Hutter V, Cook MT, et al. BioresOpen. Access. 2016; 5 (1): 94-108.

- Shegokar R, Müller RH. Int. J. Pharm. 2010; 399: 129-39.

- Song K, Zhu X, Zhu W, et al. Bioresour. Bioprocess. 2019; 6 (45):1-8.

- Strebhardt K, Ullrich A. Nat Rev Cancer. 2008; 8: 473-80.

- Sun W, Tian W, Zhang Y, et al. Nanomedicine. 2012; 8 (4): 460-7.

- Tangri P, Khurana S. Int. J. Res. Pharmaceut. Biomed. Sci. 2011; 2 (4): 1541-52.

- Thakur RR, Kashiv M. Int J Res Pharmaceut Biomed Sci. 2011; 2: 8-18.

- Van Eerdenbrugh B, Vermant J, Martens JA, et al. J. Pharm. Sci. 2009; 98 (6): 2091-103.

- Young TJ, Mawson S, Johnston KP, et al. Biotechnol. Prog. 2000;16 (3): 402-7.

- Zucca N, Erriu G, Onnis S, et al. Thermochim Acta. 2002; 143: 117-25.

Manuscript Submission

Submit your manuscript at Online Submission System

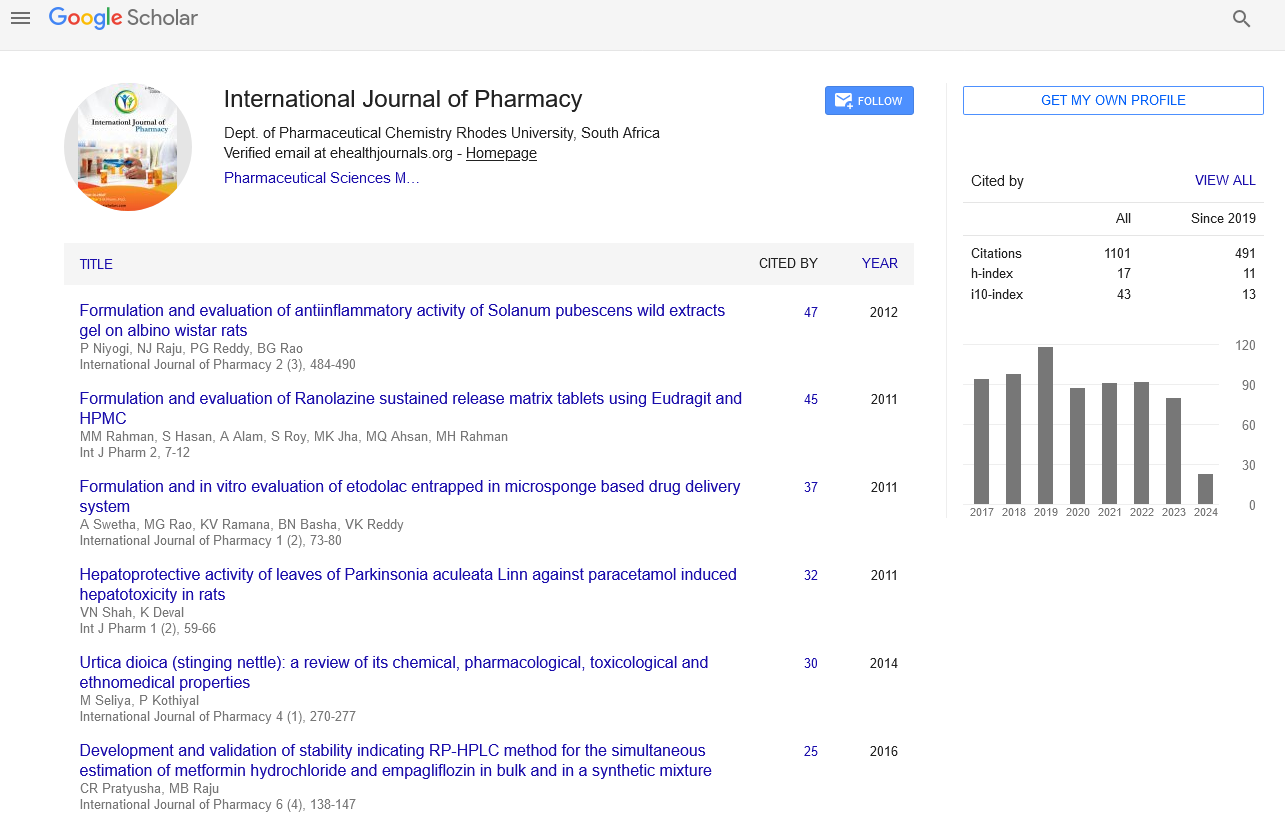

Google scholar citation report

Citations : 1101

International Journal of Pharmacy received 1101 citations as per google scholar report

International Journal of Pharmacy peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- HINARI

- Index Copernicus

- Google Scholar

- The Global Impact Factor (GIF)

- Polish Scholarly Bibliography (PBN)

- Cosmos IF

- Open Academic Journals Index (OAJI)

- Directory of Research Journal Indexing (DRJI)

- EBSCO A-Z

- OCLC- WorldCat

- MIAR

- International committee of medical journals editors (ICMJE)

- Scientific Indexing Services (SIS)

- Scientific Journal Impact Factor (SJIF)

- Euro Pub

- Eurasian Scientific Journal Index

- Root indexing

- International Institute of Organized Research

- InfoBase Index

- International Innovative Journal Impact Factor

- J-Gate