HTML

Perspective - (2024) Volume 14, Issue 4

Sustainable Practices and Technological Innovations in Pharmaceutical Engineering

Klaus Schneider**Correspondence: Klaus Schneider, Department of Pharmaceutical Sciences, University of Bonn, Bonn, Germany, Email:

Received: 01-Jul-2024, Manuscript No. IJP-24-141380; Editor assigned: 04-Jul-2024, Pre QC No. IJP-24-141380(PQ); Reviewed: 18-Jul-2024, QC No. IJP-24-141380; Revised: 25-Jul-2024, Manuscript No. IJP-24-141380 (R); Published: 31-Jul-2024, DOI: 10.37522/2249-1848.2024.14(4).119

About the Study

Pharmaceutical engineering continues to evolve rapidly, driven by technological advancements aimed at enhancing drug manufacturing efficiency, safety, and regulatory compliance. This article describes current advancements in pharmaceutical engineering, such as the use of digital technology, sustainable practices, and sophisticated production procedures. Along with streamlining production procedures, these advancements helps to create pharmaceuticals that are both safer and more potent. By using engineering concepts to optimize medication production processes, pharmaceutical engineering plays a essential role in the pharmaceutical sector. In this subject, recent advances have been concentrated on solving problems including regulatory restrictions, scalability, and cost-effectiveness. The main developments in pharmaceutical engineering are reviewed in this article along with their effects on industry practices and future directions. The transition to continuous manufacturing methods is one of the biggest developments in pharmaceutical engineering. Continuous production, as contrast to batch methods, entails a smooth, continuous flow of raw materials through various production stages. This approach offers several advantages, including enhanced process control, reduced production times, and improved product quality consistency. Continuous manufacturing also supports realtime monitoring and quality assurance, minimizing the risk of product variability and ensuring compliance with regulatory standards. In addition to continuous manufacturing, the industry has seen advancements in modular and flexible manufacturing systems. These systems allow for rapid reconfiguration of production lines to accommodate different drug formulations and production scales. By optimizing equipment utilization and minimizing changeover times, modular systems improve operational efficiency and flexibility in responding to market demands.

Pharmaceutical production is changing as a result of digital technology' improved connection, data analytics, and automation. Production processes may be monitored in real-time thanks to the use of Industry 4.0 concepts, which include IoT (Internet of Things) sensors and sophisticated analytics. IoT sensors maintain ideal conditions for medication manufacture and storage by monitoring vital characteristics including temperature, humidity, and pressure. In addition to increasing production efficiency, this data-driven strategy makes predictive maintenance easier and lowers operating expenses and downtime. Large datasets are also analysed by machine learning and Artificial Intelligence (AI) algorithms to forecast possible problems and optimise industrial processes. AI-driven insights enhance supply chain management, formulation development, and quality control decision-making, eventually improving product quality and regulatory compliance. Ensuring drug quality and safety remains a cornerstone of pharmaceutical engineering. Advanced analytical techniques, including spectroscopy and chromatography, enable accurate characterization and quantification of drug compounds and impurities. These techniques ensure compliance with pharmacopeial standards and regulatory requirements, supporting the release of high-quality pharmaceutical products into the market. Moreover, advancements in Process Analytical Technology (PAT) enable real-time monitoring and control of critical process parameters. PAT systems detect deviations from predefined specifications, allowing for immediate adjustments to maintain product quality and consistency. By integrating PAT with automated feedback control systems, pharmaceutical manufacturers enhance process robustness and minimize the risk of batch failures or recalls. The pharmaceutical industry is increasingly adopting sustainable practices to minimize environmental impact and optimize resource utilization. Green chemistry principles promote the use of environmentally benign solvents and bio catalytic processes in drug synthesis. These approaches reduce waste generation and energy consumption, contributing to sustainable manufacturing practices.

Moreover, the industry's carbon impact is decreased via programmes like recycling and energy-efficient manufacturing methods. Pharmaceutical engineers may show corporate responsibility and environmental care while also meeting regulatory standards by embracing green production procedures. Pharmaceutical engineering has advanced, yet issues with labour training, technology integration, and regulatory compliance still exist. Pharmaceutical engineers must keep up with the latest standards and compliance requirements as regulatory bodies change rules to guarantee the safety and efficacy of products. Looking forward, future advancements in pharmaceutical engineering are expected to focus on personalized medicine, biopharmaceuticals, and nanotechnology. Personalized medicine tailors treatments to individual patient profiles, improving therapeutic outcomes and patient compliance. Biopharmaceuticals, including monoclonal antibodies and gene therapies, require specialized manufacturing processes and quality control measures to ensure product efficacy and safety. Furthermore, tailored medicine delivery systems that improve drug absorption and minimize negative effects are made possible by nanotechnology. Pharmaceutical engineers can create novel medication formulations with exact control over drug release kinetics and tissue targeting by using nanoscale technology. Modern advances in pharmaceutical engineering have greatly improved the sustainability, safety, and efficiency of medicine production. The pharmaceutical industry is changing as a result of these technologies, which include advances in quality control, sustainable practices, digitization, and continuous production. Pharmaceutical engineers will advance global healthcare by navigating present obstacles and seizing future possibilities.

Manuscript Submission

Submit your manuscript at Online Submission System

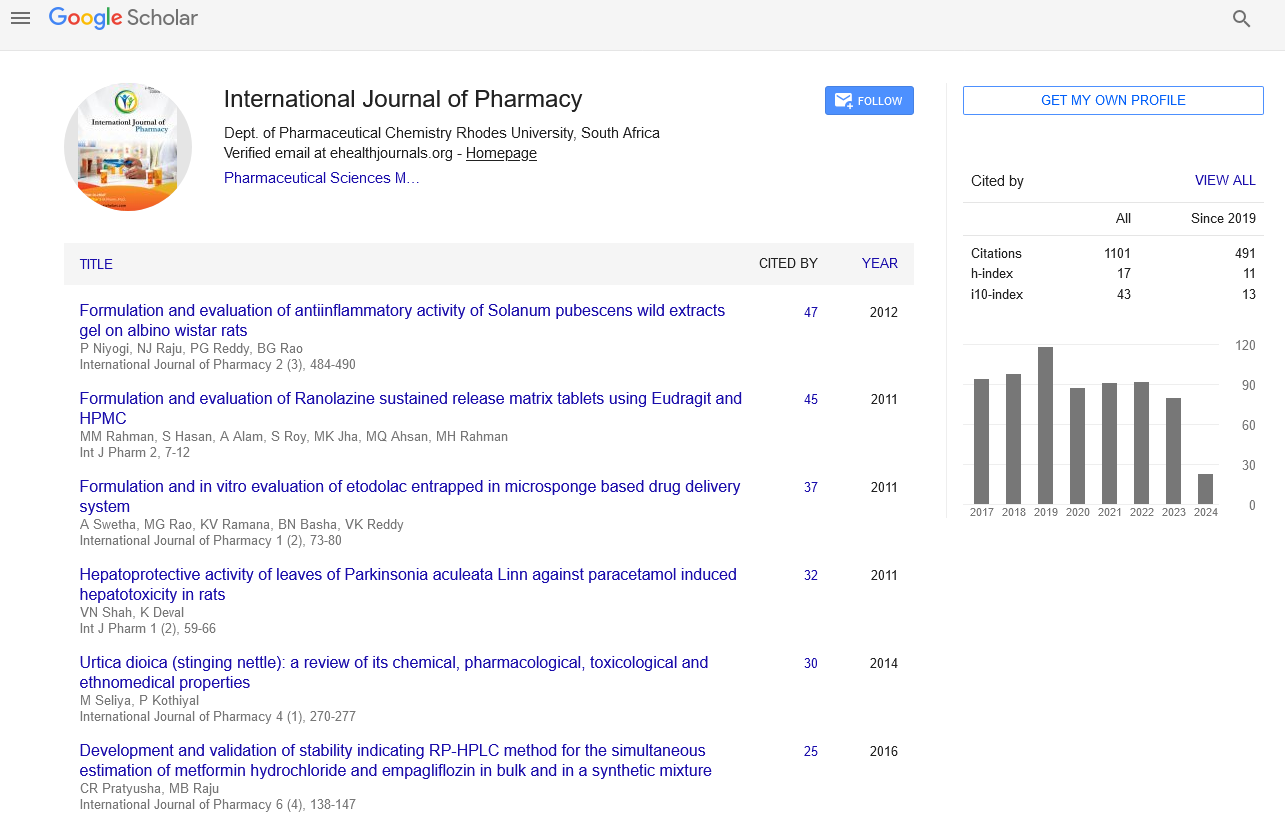

Google scholar citation report

Citations : 1101

International Journal of Pharmacy received 1101 citations as per google scholar report

International Journal of Pharmacy peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- HINARI

- Index Copernicus

- Google Scholar

- The Global Impact Factor (GIF)

- Polish Scholarly Bibliography (PBN)

- Cosmos IF

- Open Academic Journals Index (OAJI)

- Directory of Research Journal Indexing (DRJI)

- EBSCO A-Z

- OCLC- WorldCat

- MIAR

- International committee of medical journals editors (ICMJE)

- Scientific Indexing Services (SIS)

- Scientific Journal Impact Factor (SJIF)

- Euro Pub

- Eurasian Scientific Journal Index

- Root indexing

- International Institute of Organized Research

- InfoBase Index

- International Innovative Journal Impact Factor

- J-Gate